Material Wastage in Construction: Causes, Allowed Limits & Prevention

“Small improvements in material control create long-term gains on construction sites.”

Material wastage in construction is one of the most common yet least controlled problems on project sites. What often starts as small, unnoticed losses of cement, steel, sand, or bricks slowly adds up to higher project costs, delayed timelines, and reduced profit margins. In many cases, wastage is not caused by negligence alone, but by poor planning, improper storage, rework, and lack of real-time monitoring.

For contractors and project teams, understanding material wastage is no longer optional. It directly affects budgeting accuracy, procurement decisions, and overall project efficiency. Even a few percentage points of excess material consumption can significantly impact large-scale construction projects.

In this blog, you’ll learn what material wastage in construction really means, how much wastage is considered acceptable, how to calculate it correctly, and practical ways to reduce material loss on-site. The goal is simple: help you control wastage before it controls your project cost.

Material Waste Generation Is Growing Rapidly:

Annual construction waste is estimated to reach 2.2 billion tonnes globally by 2025, with projections rising to about 2.59 billion tonnes by 2030 and 3.40 billion tonnes by 2050.

What Is Material Wastage in Construction?

Material wastage in construction refers to the loss of construction materials beyond what was planned or estimated for a project. In simple terms, it is the difference between the quantity of material you intended to use and the quantity that actually gets consumed on-site.

When materials are damaged, overused, poorly handled, or left unused, they turn into wastage. While a certain level of wastage is unavoidable in construction, uncontrolled wastage leads to higher costs, frequent reordering, and poor budget control.

Definition of Material Wastage

Material wastage in construction is the excess consumption or loss of materials compared to the approved quantity estimates or BOQs.

It usually includes:

- Materials damaged during transport or handling

- Excess material ordered due to wrong estimation

- Leftover material that cannot be reused

- Material lost because of rework or poor workmanship

Simply put, if more material is used than planned without adding value to the structure, it is wastage.

Why Material Wastage Happens on Construction Sites?

Material wastage mostly happens due to execution-level issues rather than planning alone.

Common reasons include:

- Inaccurate quantity estimation during planning

- Improper storage leading to damage or spoilage

- Poor supervision and lack of accountability

- Frequent design changes and rework

- Unskilled handling of materials at the site

- No system to track daily material consumption

Most wastage is gradual and unnoticed. By the time it shows up in cost reports, the damage is already done. This is why early awareness and monitoring are critical on every construction site.

What Is Waste Material in Construction?

Waste material in construction refers to any material that is no longer usable for its intended purpose on a project site. Unlike material wastage, which focuses on excess consumption, waste material is the physical output that remains after work is completed or disrupted.

In simple terms, wastage is about how much extra material is used, while waste material is what is left behind or thrown away.

Waste material can appear at different stages of construction. It may be generated during cutting, mixing, demolition, rework, or even at the final finishing stage. Some waste is unavoidable, but a large portion comes from poor planning, improper handling, and a lack of reuse strategies.

When not managed properly, waste material increases disposal costs, creates site clutter, and contributes to environmental harm. Identifying and controlling waste material is a key step toward cleaner, more cost-efficient construction practices.

Common Examples of Waste Material in Construction

Some of the most commonly generated waste materials on construction sites include:

- Broken or damaged bricks and blocks

- Hardened or unused cement and mortar

- Steel cut-offs, scrap bars, and wires

- Leftover concrete after casting

- Cracked or rejected tiles and fittings

These materials often end up discarded, even though better planning and monitoring could significantly reduce their volume.

How Much Wastage Is Allowed in Construction?

In construction, zero wastage is unrealistic. Every project involves cutting, handling, transportation, and on-site adjustments. Because of this, the industry allows a controlled percentage of material wastage during planning and estimation.

However, the keyword here is controlled. Allowed wastage is meant to cover unavoidable losses, not poor execution or mismanagement. When wastage crosses acceptable limits, it directly affects project cost and profitability.

Understanding how much wastage is allowed helps contractors:

- Plan material procurement accurately

- Avoid frequent shortages or over-ordering

- Identify abnormal losses early

- Maintain budget discipline

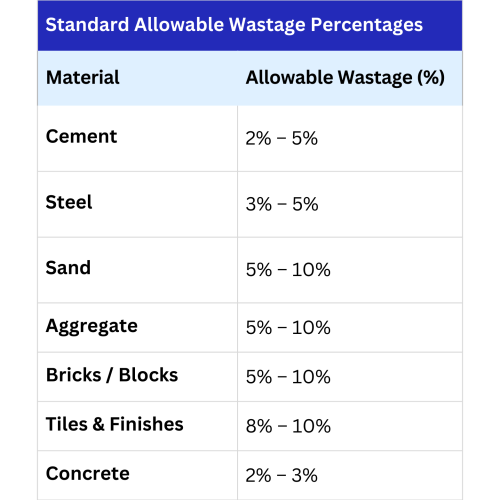

Standard Allowable Wastage Percentages

While exact numbers may vary by project type and site conditions, the following ranges are commonly accepted in construction practice:

These percentages are usually added during estimation to ensure smooth execution without material shortages. Projects with better storage, skilled labor, and close supervision often achieve wastage at the lower end of these ranges.

When Wastage Becomes a Cost Overrun

Wastage turns into a cost overrun when actual material consumption exceeds the planned allowance.

This usually happens due to:

- Rework caused by poor workmanship

- Improper storage leading to damage

- Theft or pilferage

- Lack of daily material tracking

- Frequent design changes

Once wastage crosses allowable limits, it silently eats into margins. The project may still progress on schedule, but the final cost tells a different story. This is why monitoring material usage throughout the project is just as important as planning it at the start.

How to Calculate Material Wastage in Construction?

Calculating material wastage in construction helps you plan procurement accurately and control cost leakages early. When wastage is calculated correctly, you avoid both shortages and unnecessary over-ordering. The process is straightforward and can be applied to various materials, including cement, steel, tiles, and sand.

The key is to compare the planned material quantity with the actual site consumption. This comparison determines whether wastage is within allowable limits or is becoming a cost risk.

Basic Wastage Calculation Formula

Material wastage is calculated using a straightforward percentage formula:

Wastage Quantity = Required Quantity × Wastage Percentage

This formula helps you estimate the amount of extra material that should be considered during planning to account for unavoidable losses.

For example, if your BOQ says you need a certain quantity of material, adding a predefined wastage percentage ensures smooth execution without frequent reordering.

This calculation is usually done:

Material wastage is calculated using a straightforward percentage formula:

Wastage Quantity = Required Quantity × Wastage Percentage

This formula helps you estimate the amount of extra material that should be considered during planning to account for unavoidable losses.

For example, if your BOQ says you need a certain quantity of material, adding a predefined wastage percentage ensures smooth execution without frequent reordering.

This calculation is usually done:

- During estimation and budgeting

- Before material procurement

- While reviewing planned vs actual consumption

Example: How to Calculate 10% Wastage

Let’s understand this with a simple example.

Assume:

- Required material quantity = 100 units

- Allowed wastage = 10%

Step 1: Calculate wastage quantity

100 × 10 ÷ 100 = 10 units

Step 2: Calculate total material to be procured

100 + 10 = 110 units

To complete the work without shortages, you should plan for 110 units, with 10 units allocated for possible wastage.

This same method applies to any material. Regularly comparing planned quantity with actual consumption helps you detect excessive wastage before it affects project costs.

Want to track material consumption more accurately at the site level?

Modern digital material tracking systems help teams compare planned quantities with actual usage in real time, making it easier to spot wastage early.

Major Causes of Material Wastage in Construction

Material wastage in construction rarely comes from a single mistake. It is usually the result of small gaps across planning, storage, execution, and supervision. When these gaps combine, wastage slowly increases and becomes difficult to control. Understanding the root causes is the first step toward reducing material loss on-site.

Poor Material Planning & Estimation

Inaccurate planning is one of the biggest contributors to material wastage. When quantity estimates are rushed or based on assumptions, materials are either over-ordered or fall short.

Common planning issues include:

- Incomplete or outdated BOQs

- Incorrect wastage percentages were applied during estimation

- Poor coordination between design and execution teams

When planning is weak, excess material often remains unused or gets damaged before it can be consumed. This leads to unnecessary cost and storage issues.

Improper Storage and Handling

Even well-planned materials can turn into waste if they are not stored or handled correctly on-site. Construction materials are sensitive to weather, moisture, and rough handling.

Typical storage-related causes include:

- Cement exposed to moisture

- Steel is stored without proper stacking

- Tiles and fittings were aged during the shifting

- Sand and aggregates mixed with debris

Improper handling during unloading, movement, or usage further increases breakage and spoilage, especially on congested sites.

Rework and Design Changes

Rework is a silent driver of material wastage. When work has to be redone, previously used materials often become unusable.

This usually happens due to:

- Errors in drawings or execution

- Poor workmanship

- Late design changes by clients

- Lack of clarity during site instructions

Rework not only wastes material but also increases labor cost and delays the project schedule.

Lack of Monitoring and Accountability

When material consumption is not tracked daily, wastage goes unnoticed. Without clear accountability, losses are often ignored until the final cost review.

Key gaps include:

- No comparison between planned and actual consumption

- Manual tracking with delayed reporting

- No responsibility assigned for material control

Without regular monitoring, wastage becomes habitual rather than exceptional. Consistent tracking and accountability are essential to keep material usage under control.

Impact of Material Wastage on Construction Projects

Material wastage may look like a site-level issue, but its impact goes far beyond unused materials. When wastage is not controlled, it directly affects project cost, timelines, and environmental responsibility. These effects often appear gradually, making them harder to detect until the damage is already done.

Cost Impact

Material wastage has a direct and immediate effect on project finances. Every extra bag of cement or unused steel bar adds to the overall cost without adding value.

Uncontrolled wastage leads to:

- Higher material procurement costs

- Increased transportation and storage expenses

- Reduced profit margins for contractors

- Budget overruns that affect cash flow

Even a small percentage increase in wastage can result in significant financial loss on large projects.

Schedule Delays

When materials are wasted, projects often face unexpected shortages. This disrupts planned workflows and slows down execution.

Common delay-related issues include:

- Work stoppages due to material unavailability

- Time lost in reordering and approvals

- Rework caused by poor-quality execution

These delays affect not just timelines but also labor productivity and coordination across teams.

Environmental Impact

Material wastage also has a serious environmental cost. Discarded construction materials contribute to landfill waste and resource depletion.

Excess wastage results in:

- Increased construction debris

- Higher carbon footprint from material production

- Poor sustainability performance

Reducing wastage supports cleaner sites, responsible resource use, and more sustainable construction practices overall.

Why Small Reductions in Wastage Matter?

Even a 2–3% reduction in material wastage can make a noticeable difference in construction projects, especially large ones. What seems minor on paper often translates into significant savings on-site.

How to Reduce Material Wastage in Construction?

Reducing material wastage in construction is not about cutting corners. It is about planning smarter, executing carefully, and monitoring consistently. Most wastage can be controlled with practical site-level discipline and better coordination between planning and execution teams.

Here are the most effective ways to reduce material wastage on construction projects.

Accurate Planning and Procurement

Wastage control begins long before materials reach the site. Accurate planning ensures that the right quantity is ordered at the right time.

Key practices include:

- Preparing detailed and updated BOQs

- Applying realistic wastage percentages during estimation

- Avoiding bulk ordering without consumption planning

- Coordinating closely between design, planning, and procurement teams

When planning is precise, excess materials are minimized, and the risk of leftover or damaged stock is reduced significantly.

Proper Storage and Site Practices

Even well-planned materials can turn into waste if site practices are poor. Storage conditions and handling methods play a major role in material preservation.

Good site practices involve:

- Storing cement in dry, covered areas

- Proper stacking of steel, tiles, and blocks

- Protecting materials from weather exposure

- Training workers on correct handling methods

Clean, organized storage areas not only reduce wastage but also improve site safety and efficiency.

Site-Level Monitoring and Reporting

Material wastage often increases when daily consumption is not tracked. Regular monitoring helps identify issues early, before losses become serious.

Effective monitoring includes:

- Recording daily material usage

- Comparing planned quantities with actual consumption

- Investigating abnormal variations immediately

- Assigning clear responsibility for material control

When site teams know that material usage is being monitored, accountability naturally improves.

Use of Digital Construction Management Tools

Manual tracking makes it difficult to spot wastage patterns. Digital tools simplify material control by providing real-time visibility.

These tools help by:

- Tracking material inflow and outflow accurately

- Generating consumption reports automatically

- Highlighting excess usage early

- Improving coordination between the site and office teams

Technology does not replace good site practices, but it strengthens them. When combined with disciplined execution, digital tools make waste control more practical and sustainable across projects.

Conclusion

Material wastage in construction is not just a site issue. It is a management challenge that reflects how well planning and execution are aligned. When wastage is ignored, project costs rise quietly, and margins shrink without warning. When it is controlled, projects run smoother and resources are used more responsibly.

The key lies in discipline. Accurate planning, proper storage, skilled execution, and regular monitoring work together to keep material usage within limits. Small improvements in daily practices often lead to significant long-term savings.

Controlling material wastage does not require complex changes. It requires awareness, accountability, and consistency across teams. When planning teams and site teams work in sync, wastage naturally occurs.

In the end, effective material control is about building smarter. It protects project budgets, supports sustainable practices, and helps construction teams deliver quality work without unnecessary loss.

Moving Toward Smarter Material Control

Modern construction teams are increasingly turning to digital tools to gain better control over material usage. These tools don’t replace site experience. They support it with clarity and real-time insight.